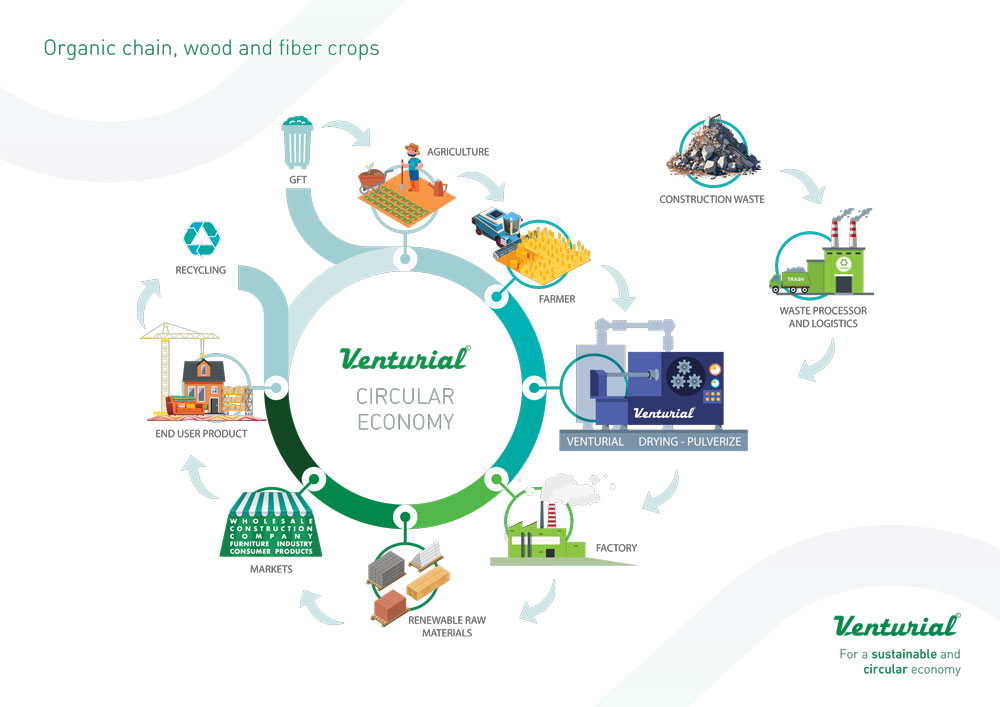

The Venturial Group manages and operates its own innovative drying and pulverizing technology. This advanced technology has been developed with a strong focus on sustainability and the principles of a circular economy. The system offers the possibility to dry and pulverize both organic and inorganic materials in a single integrated process in a sustainable and CO₂-neutral way. In this way, the Venturial technology makes a valuable contribution to the realization of new circular production flows.

The basis of Blue Economy is holistic systems thinking, in which the whole and the connections are as important as the individual parts. By applying new scientific insights, Blue Economy comes up with technological solutions, regionstrengthening economic principles and new business models. In nature, there is no waste. This means that we see waste as a raw material for new products. Every part of every product must be reusable or biodegradable. By linking technical innovations to our ecosystem, we can reduce waste streams and thus realize a new industrial policy. The Venturial delivers a demonstrable sustainable contribution as a link to the redesign of new business chains. This is done by seeing waste/residue streams, which are currently taken to the incinerators, as new materials (building materials). The sustainable opportunities to produce renewable raw materials can, through the technology of the Venturial, make an absolute contribution to the establishment of cross-sectoral chain innovations.

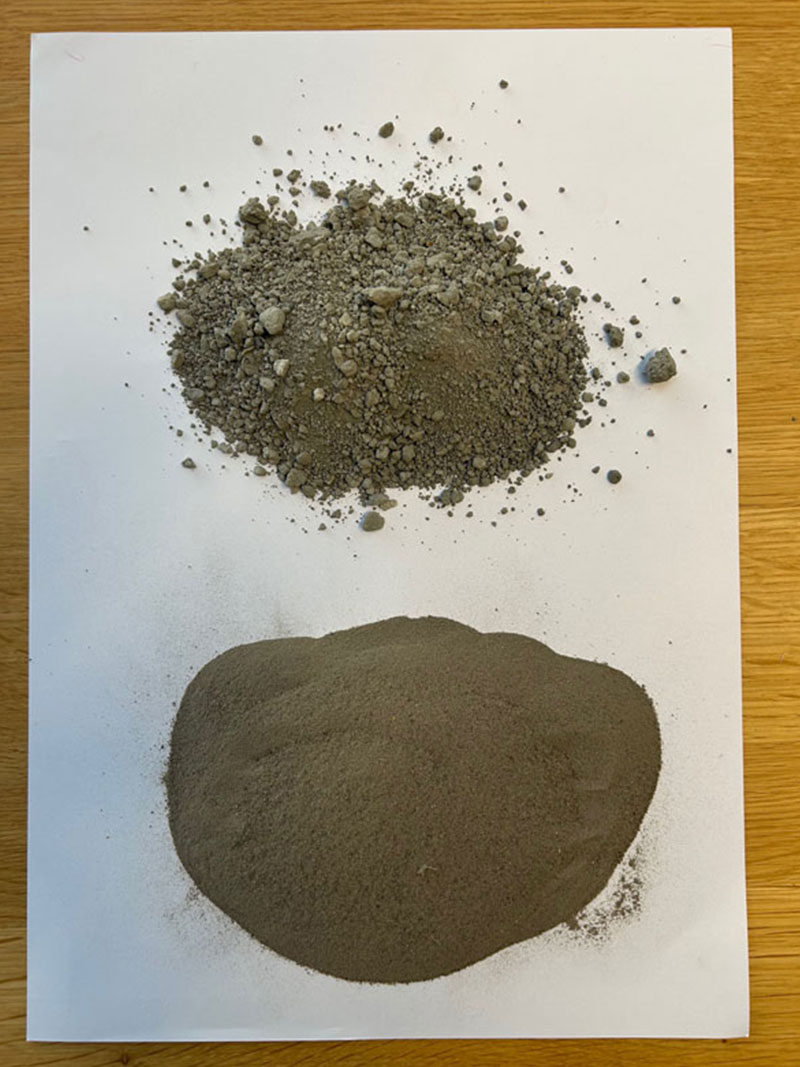

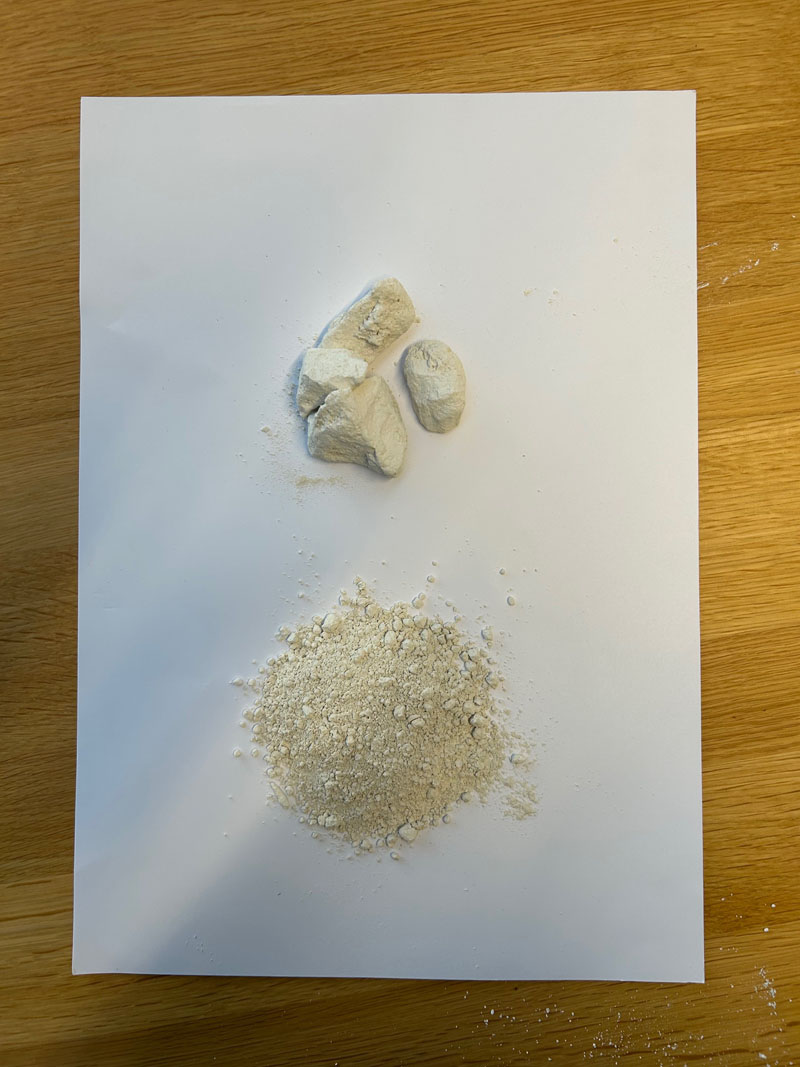

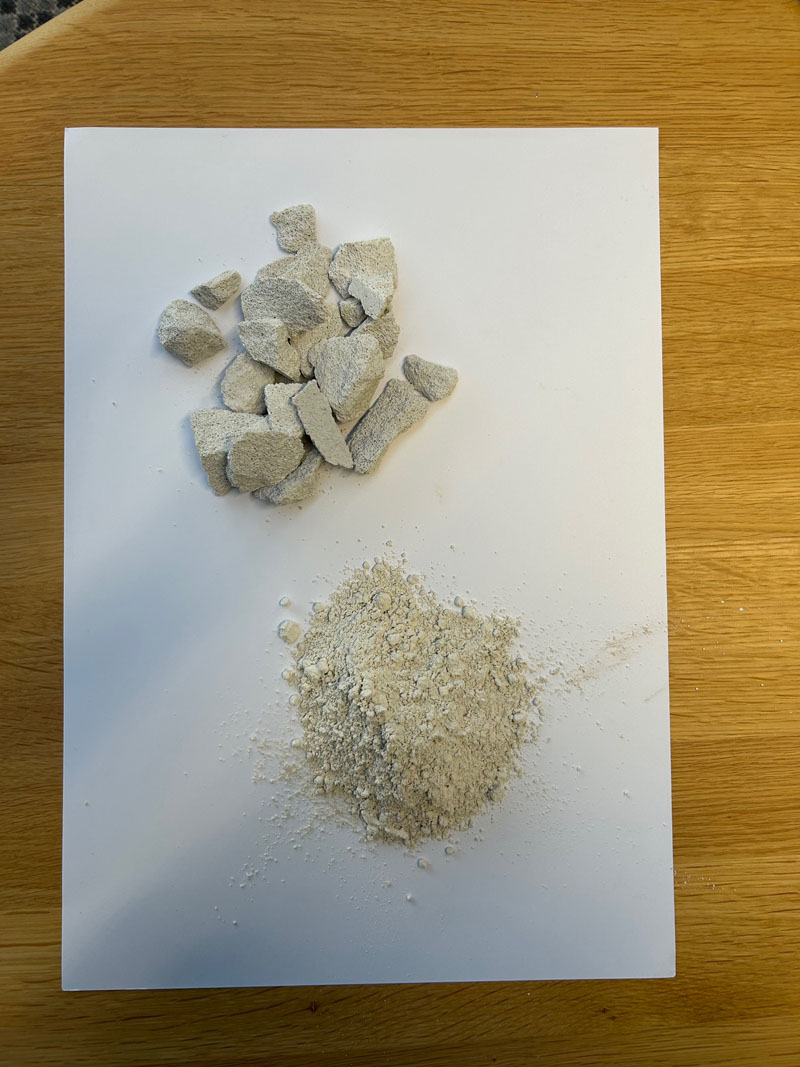

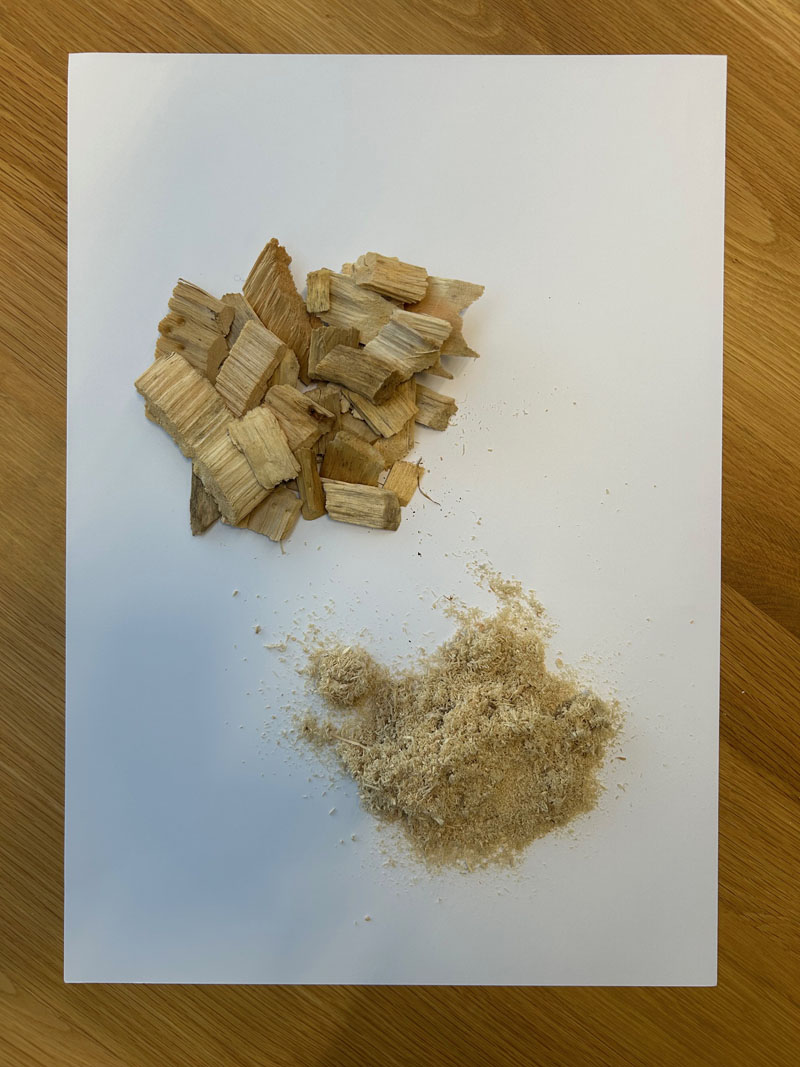

Drying and pulverizing organic and anorganic materials makes new separation technologies possible and provides new raw materials back into the chains. The drying and pulverizing technologies then provide the raw materials to produce new products, materials and processes. We have now tested around 40 waste and residual streams, with positive results.

This Venturial dryer technology kills micro-organisms by extreme air pressure drop and acoustic shock waves. It is a physical process whereby materials are accelerated through the sound barrier and subjected to extreme acoustic shock waves. These materials disintegrate and immediately lose a very large percentage of their moisture content in one cycle, depending on the material and the ambient humidity. The Venturial technology enables immediate drying. It is an immediate conversion of a “hard” raw material (max 2.5 – 4 cm size input). This technology preserves the high quality ingredients of the materials.

• No heat exhaust only water vapor.

• No chemicals.

• No drying agents.

• No fossil fuel or propane gas.

• No exhaust gases.

• Freshness and quality are not affected.

• No compression of organic materials.

• No loss of ingredients.

• Immediate preservation of crops.

• Eliminates mold, mildew, bacteria.

• Pulverizing and drying in one cycle

• Quality control of the output product can be predetermined

• Can be processed directly in extraction or storage systems.

Development of new circular systems.

• VENTURIAL TECHNOLOGY is a high-quality link in the

sustainable chain innovation.

Basically, the Venturial can process a lot of waste/ residue streams. Besides drying and pulverizing organic substances, the Venturial can also dry pulverize inorganic substances such as glass, cement, and plaster. The starting point is that the material can be imported at a maximum size of 4 cm. The amount of moisture and the reduction in size of the material is interrelated and can always be tested experimentally. Each Venturial is a BASIC machine with subsequent 15%- 20% customer-specific adjustments. On request, we can make a small one (50 kilograms) and run a bi g test with your material (maximum of 1000-2000 kilos). The results of the test will be received by the customer with the associated parameters that will be discussed in advance. The test results for laboratory and further research, with the associated parameters, will be forwarded to the customer.

This is your chance to emphasize why the visitor should contact you right now.